We exited the warehouse and walked along Zum Heilbach to see the R&D Department and Factory Museum

All Sonor products are designed in house by these folks on PC's running a CAD program. The prototypes are then built in the metal fab onsite or sent to a facitlity that laser cuts parts out of a plastic compound. What comes back is a perfectly formed example of the part that can then be sent away to make a final production mold.

Wall Art in the R&D office. Isn't this the band Steve Smith was in before Vital Information? Name "Escapes" me...

Next door is the factory museum.

A 1950 era kit.

A Nussbaum Hilite kit in bop sizes...

Interesting variation on the Leedy & Ludwig "Knob Tension" drums. This design is much better and very well thought out.

Turn the crank on the side and there is a mechanism inside that pushes the bearing edge against the head. I don't know whether this one came first or the L&L which was designed by George Way, but L&L's complete failure in the market probably doomed this one as well.

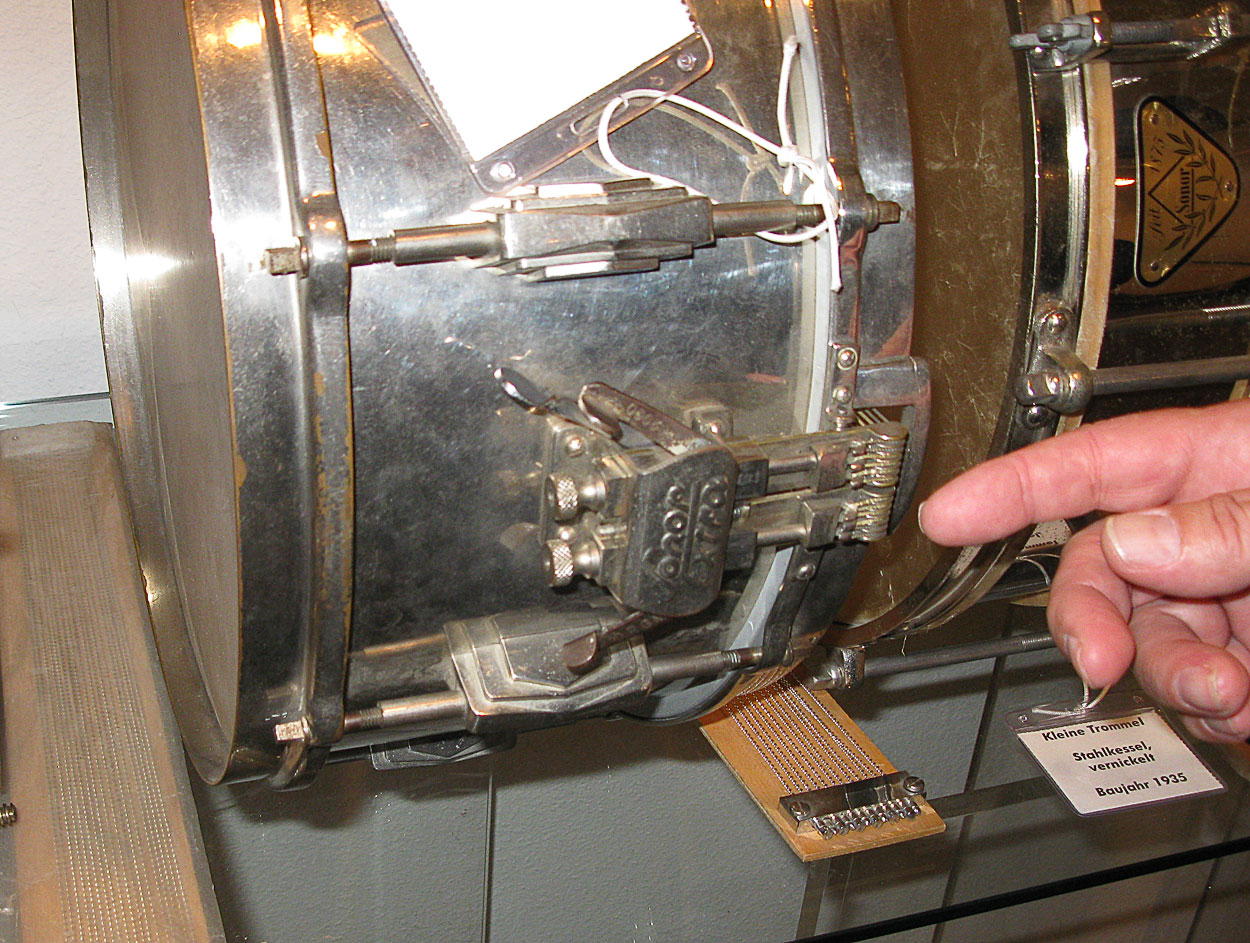

Another interesting variation on a theme. Karl is pointing out the dual strainer on this "Sonor Extra" Concert snare from around 1935. What really caught my eye is the lugs which bear a striking resemblance to the Ludwig Imperial lug which was introduced in 1936 on their "Silver Anniversary" snares. The designs aren't exact, but very close indeed. Again, which came first, the Ludwig & Ludwig or the Sonor? Hard to tell.

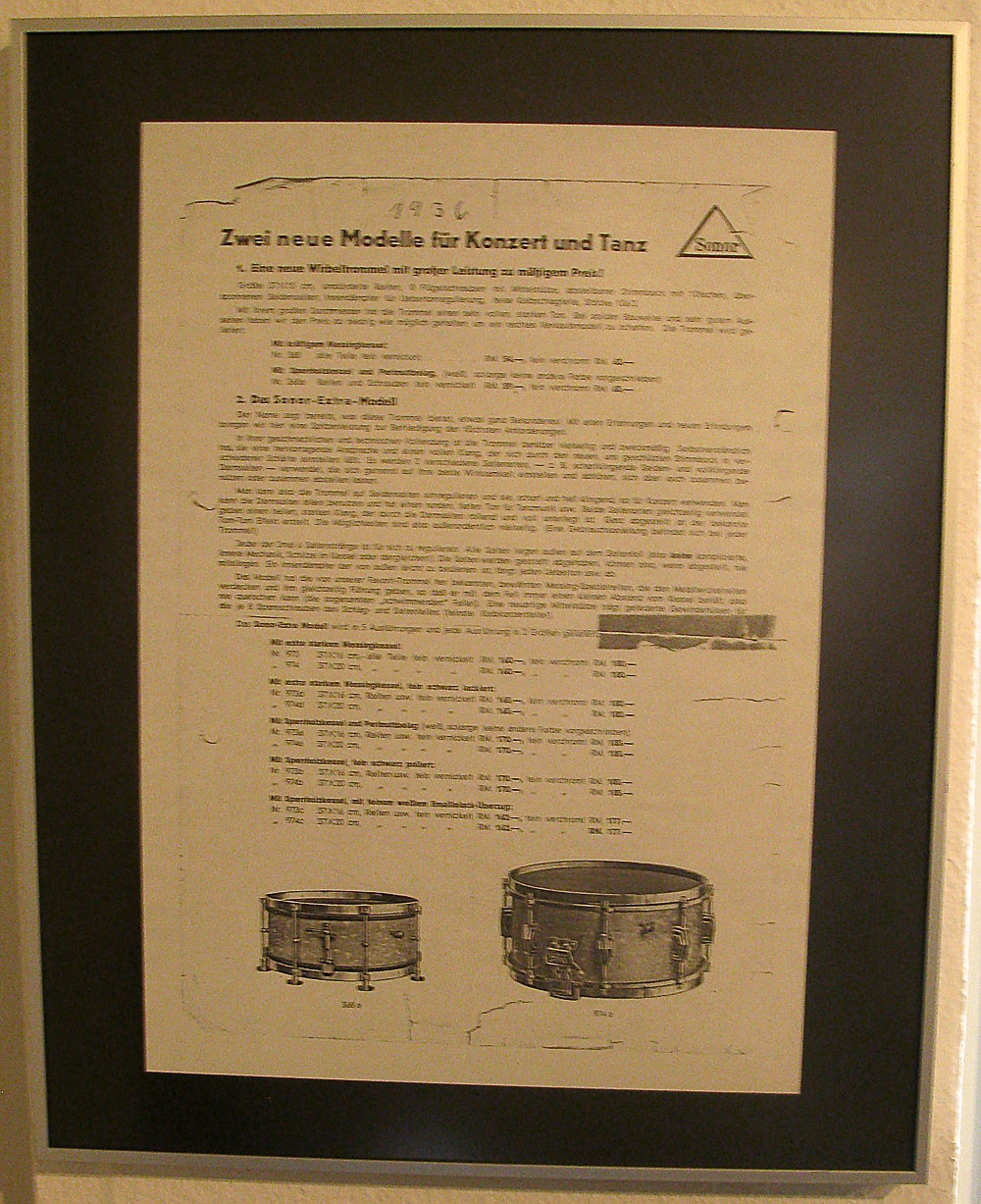

The 1936 catalog page showing the "Sonor Extra"

Various snare drums - on the left a wood shell snare in WMP wrap, the other appears to have an enameled metal shell.

Tympani

Ancient Glockenspeil circa 1890

Another glockenspeil from the mid 30's

(though I thought the paper inverted triangle badge is from the immediate post-war period)

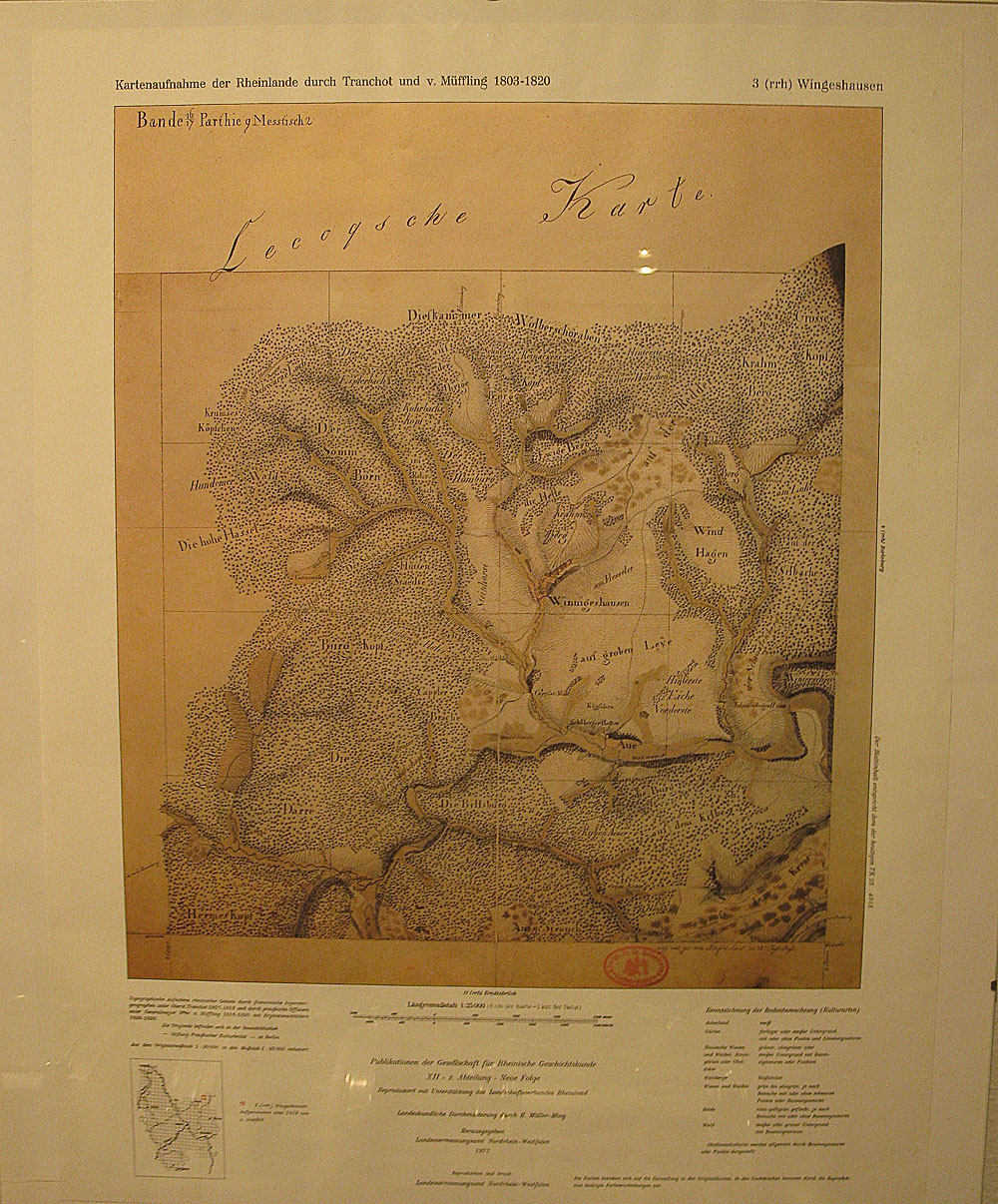

Map of the surrounding area from the early 1800's.

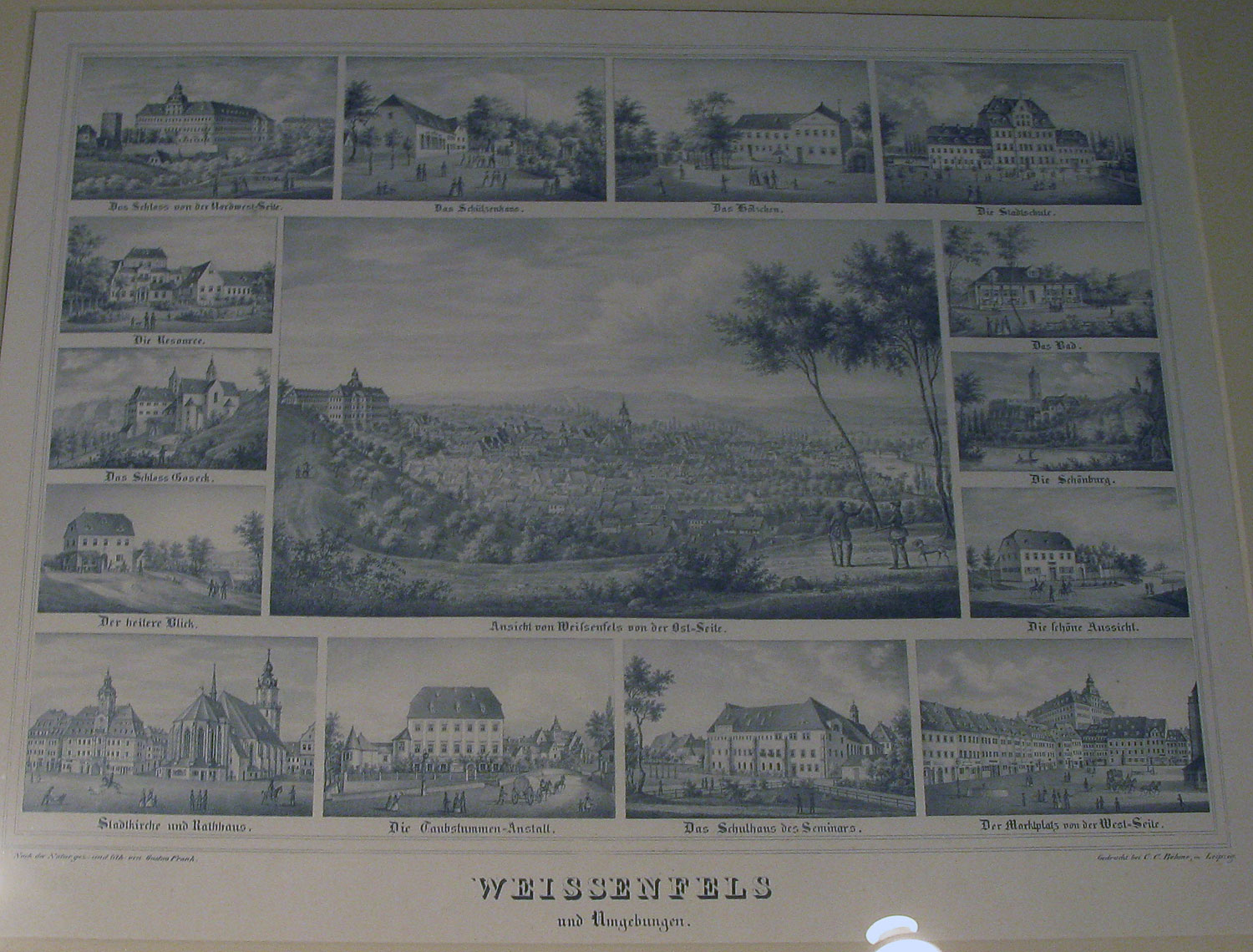

Poster of the sights of Weissenfels - the prewar home of Sonor

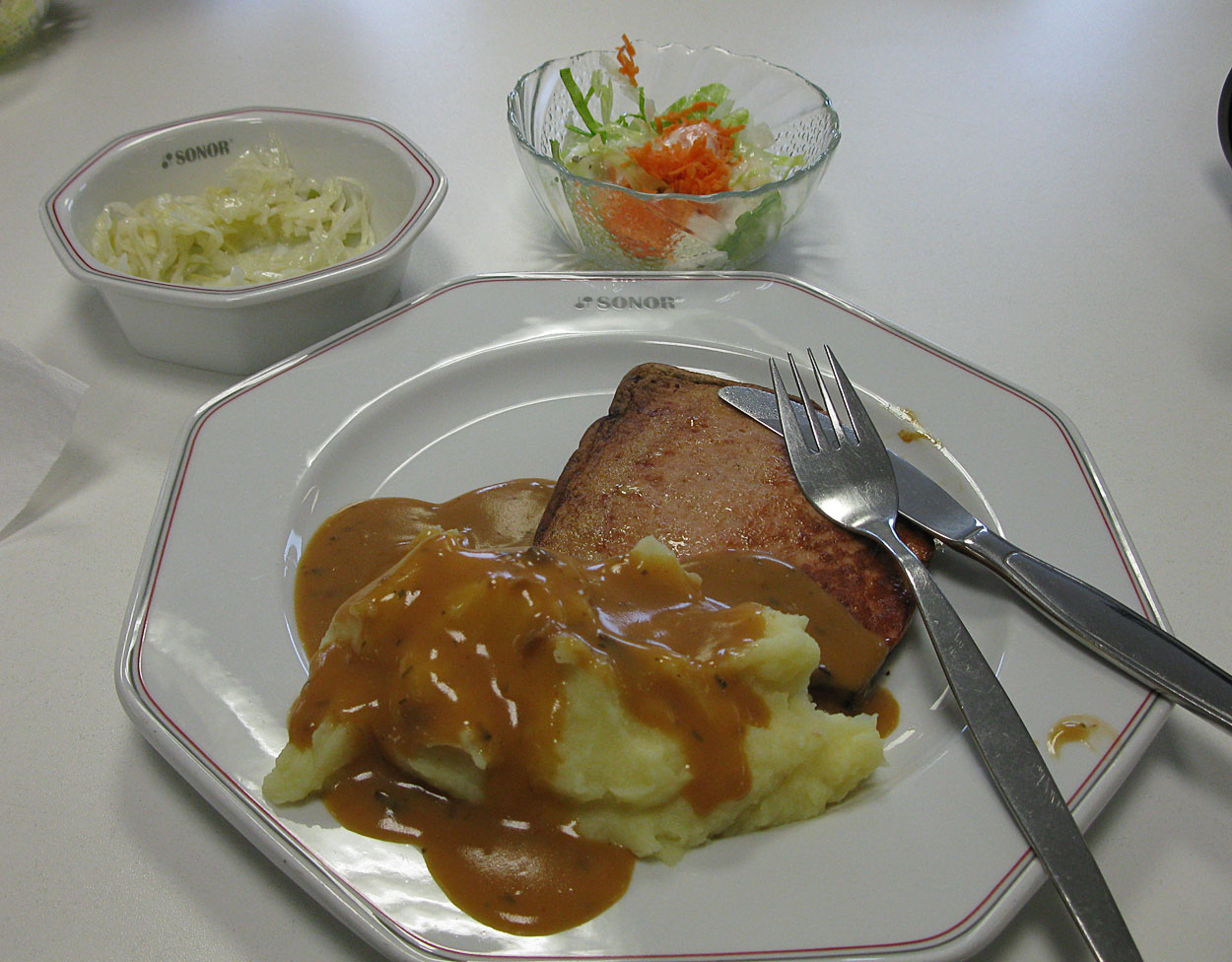

Then, to the Sonor Canteen for lunch!

The entree was a southern German dish, "Leberkasse" or "Liver Cheese". No liver in it that I could tell and it was quite tasty.

The Sonor Jet Set - one of only 25 made

Poster in the canteen

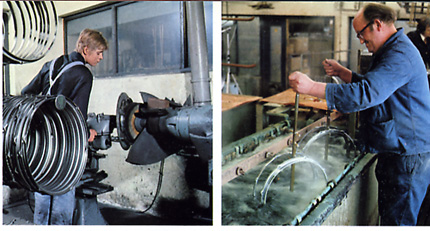

I did ask a few questions about some things I didn't see. For one, the seamless fabrication machine that so often comes up in conversation on the board.

For those who don't know, Sonor at one time made their own seamless metal snare shells and hoops in-house on this machine and did their own plating as well.

For those who don't know, Sonor at one time made their own seamless metal snare shells and hoops in-house on this machine and did their own plating as well.

Here is the story and it's actually twofold. Number one, Sonor had been buying the ferromanganese steel blanks from a metal company that also suplied the same alloy to the auto industry. In the mid 1990's the auto maker who bought this alloy stopped using it. Karl explained that he could still get the alloy but had a minimum buy of something like 50 tons. Needless to say they hadn't used anywhere near that much ferro steel over the previous 25 YEARS so that pretty much ended that. The other whammy came in the mid 1990's from the German version of the EPA. They mandated that water discharged from the manufacturing facility had to exceed the purity standards for bottled water! Chrome plating is an inherently nasty and dirty business with all kinds of corrosive chemicals and heavy metals involved. Sonor had already spend a LOT of money on new filtration equipment to meet the previous standards. It simply became too expensive to do any plating in-house and also meet the federal guidelines. In two fell swoops THAT, my friends, is what killed the ferro snares. The machine sat idle for the next few years and was eventually sent to China about the year 2000. They were using it to make trumpet and trombone bells with varying degrees of success. It is rumoured that the machine may have ended up in the Netherlands as there is a supplier there who is making seamless metal goods to spec. Their cost per unit for drum shells is exceedingly high and thus it appears we have seen the last of our beloved seamless ferro snares and drum hoops.

Speaking of drum shells, the question of the cast bronze shells also came up in conversation -

Sonor started out with one supplier in the late 1980s when the HLD 590 and 593 were first introduced. Apparently the failure rate is very high in the casting process - at least in regards that we Sonor afficionados are very picky about how our drums LOOK as well as sound. So many shells were sent back with cosmetic imperfections that the supplier simply gave up. Sonor was forced to find another supplier. I don't know when that actually happened, but that may account for the slight color variation seen by some of you between the early and current shells. The relatively low production and high quality standard also assure that the drums will be expensive.

My 3 day trip to Germany was jam packed from start to finish. Karl and David were generous and gracious hosts. I am very proud to call them my friends and to be a member of the Sonor family.

I can't wait to go back, stay longer and see more of this wonderful country.

Finis